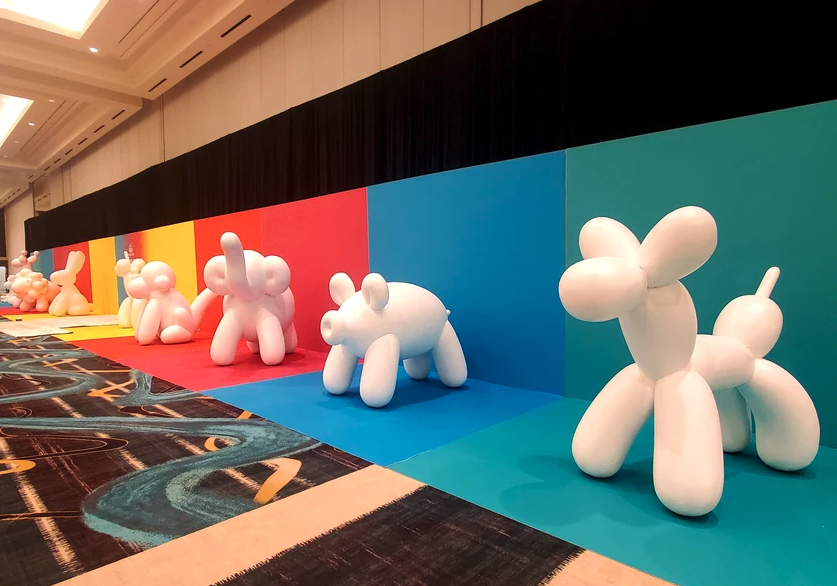

UMLF: Hey Will! We're excited to interview you as our Business of the Month for Xtreme Foamworx. Can you introduce yourself to our readers? "I am Will Laird; I grew up on a large cattle ranch outside Evanston, Wyoming, where I acquired many skills I use in my business today. Grit, hard work, and determination that I can do anything are some of those skills I use. I have lived in the St George area for five years. My wife and I have come to enjoy the St George area and the people we know in this area. I am the father to 2 amazing boys who are in sports and school. I volunteer as a football coach on my son's team and enjoy fishing and hunting when I get the time to do so." UMLF: Tell us about Xtreme Foamworks and why you decided to start it. Will: "Xtreme Foamworx is a custom foam fabrication business. We take large billets of foam and make almost anything a person can think of out of that foam to serve its purpose. I have been in this industry for 10+ years now and have made a point to be the one to make the "impossible" possible. We started the business because we desired to take more control of our financial future and to serve the area with a local shop to handle the needs of our growing city. When I moved down to St George, I left a similar business up in Utah county and had many business friends who wanted us to start a foam company. So we started up Xtreme Foamworx LLC. We started with a 5000 sq ft shop in Evanston, Wyoming and a portion of the shop in St George. We made many weekly trips up and back to the Wasatch Front to get materials and deliver goods. After a year and a half, we could start completing truckload orders and making fewer trips with more work. In 2019 we hired our first employees in the St George area, and things took off." UMLF: For someone who isn't familiar with foam fabrication, what are some of the things people can order from you? Will: "At Xtreme Foamworx, we make custom stuff. We have helped make prototypes to large runs of architectural shapes for the stucco to packaging components for all types of products. We have become known for our large sculptures. We serve anyone from a single person to large-scale businesses." UMLF: You get to work on so many cool things. Do you have a favorite project you can tell us about? Will: "Some of my favorite projects we have worked on have been the big ones! The 1st large project we took on was the Evermore Park pumpkins. This project tested our new business in 2018 to produce 26 pumpkins that would range in height from 6ft tall to 24' tall. We had five weeks to create these and made it on schedule. Another project was a much more recent one, and that was working with Tuacahn Theatre on their sets for the 2022 summer shows. We made large props and set pieces that they designed. We made the parts with different foam densities and hard coats, and then they did the magic of scenic painting for a fantastic set. One last one was from 2021. Paparazzi reached out to us,and we had to excellent opportunity to make some amazing sculptures for their event in Las Vegas. We made ten balloon animal sculptures that were 6 ft tall to 10 ft tall and some signs and large letters. Lots of creativity, time, and hard work went into each project. I don't always know the exact method. I will build some of the projects that come, but we always find a way. What makes these projects my favorite is the creative aspects we had to approach these with to make them." UMLF: What would your dream project be? Will: When we get creative projects, we always enjoy them and their challenges. The dream project is creative, complex, and fully funded. I would love to make the dream set sculpture or feature for someone with the budget to do it and the timeframe to make it fit their dreams. UMLF: Entrepreneurship has its highs and lows. Can you tell us about a challenge you faced a small business owner and how you overcame it? Will: "One of our toughest challenges was getting our funding into place once we established business. We were initially funded by a family friend who gave us a three-year loan to build machines and get up and going. Once we had the machines built and business was moving forward, we realized we needed to grow to be more successful. In the last two years, we have struggled with establishing credit limits with our vendors as we didn't have a company credit card until last year. We had to pay for all materials upfront, and most customers would pay COD or net 15. As we have grown our customer base to larger companies, they will extend us to a net 30-45. I had to be the squeaky wheel and push to meet with the right people to get our credit line with our leading supplier. This was a six-month struggle, with me persisting with my sales rep, his supervisor, and the company's vice president to arrange a meeting to get set up. Once I accomplished the line of credit has helped us grow and maintain a much better cash flow." UMLF: How has the Utah Microloan Fund has helped your business? Will: "Utah Microloan Fund was vital in helping us gain the working capital we needed to grow our workforce to handle our increased workload. The process with UMLF was straightforward. We had a guiding hand through the process; if any questions arose, we had someone to reach out to and help. We have been highly grateful for the willingness of UMLF to help small businesses that banks want to turn away before they know the business. I have recommended the UMLF to many entrepreneur friends in the state to get their businesses to the next step." To check out more from Xtreme Foamworx visit: Website: www.xtfoam.com Facebook: www.facebook.com/Xtfoam Instagram: www.instagram.com/xtreme_foamworx

0 Comments

Leave a Reply. |